position:Home > Products > Sheet metal deburring equipment

|

|

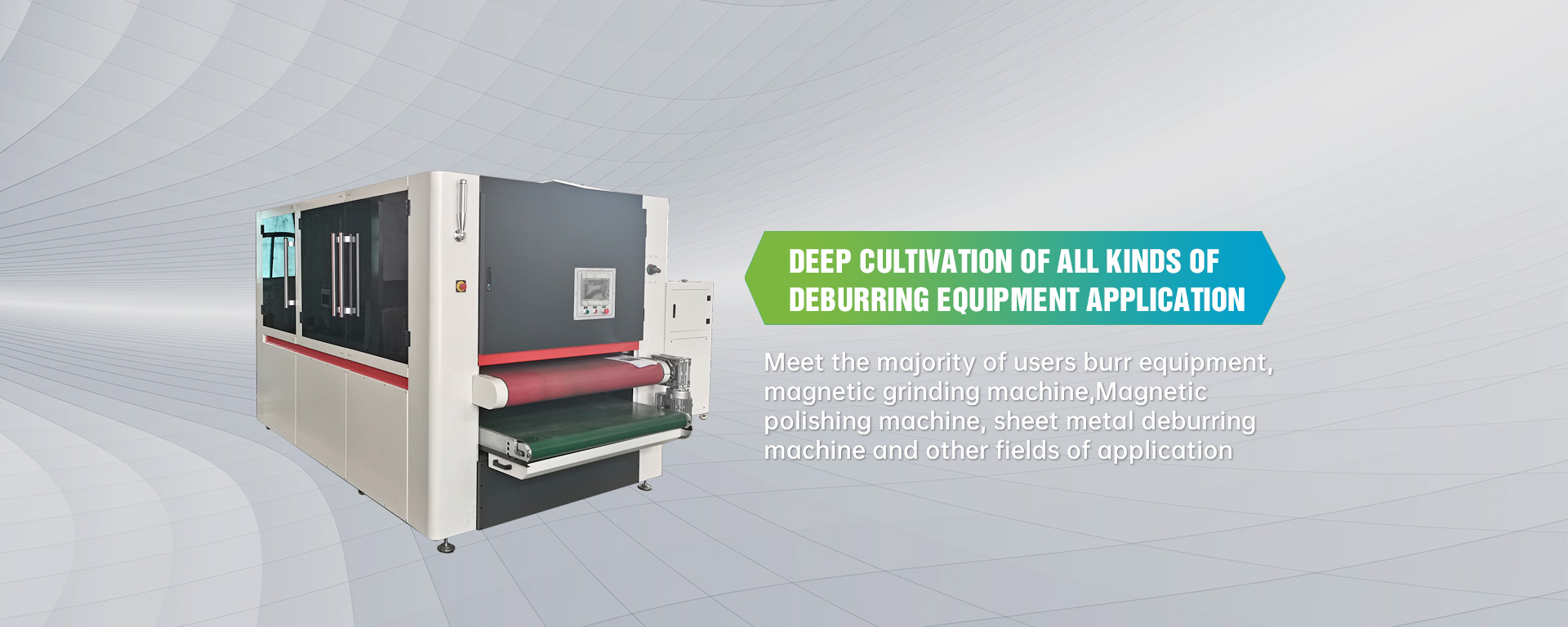

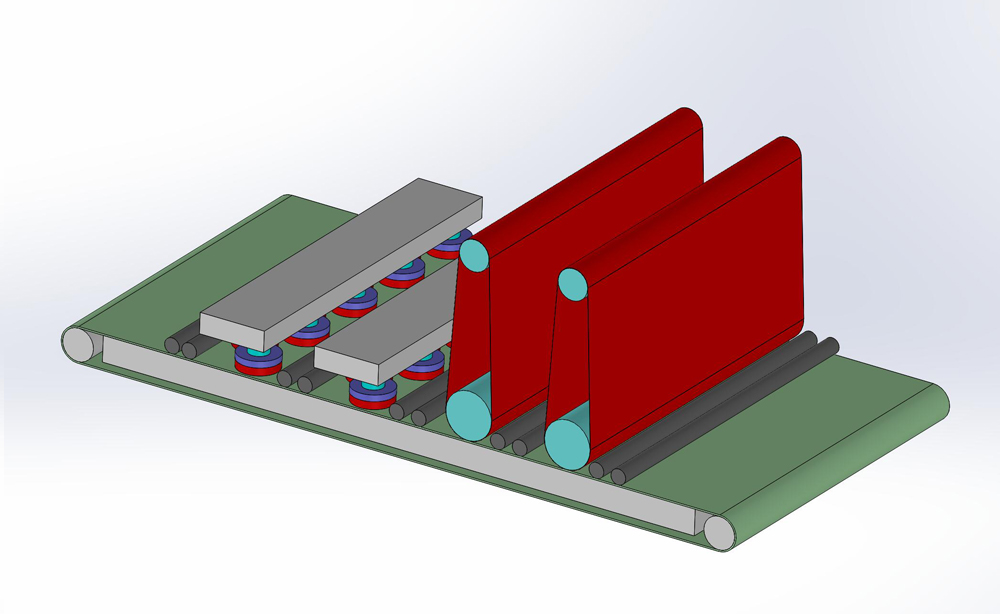

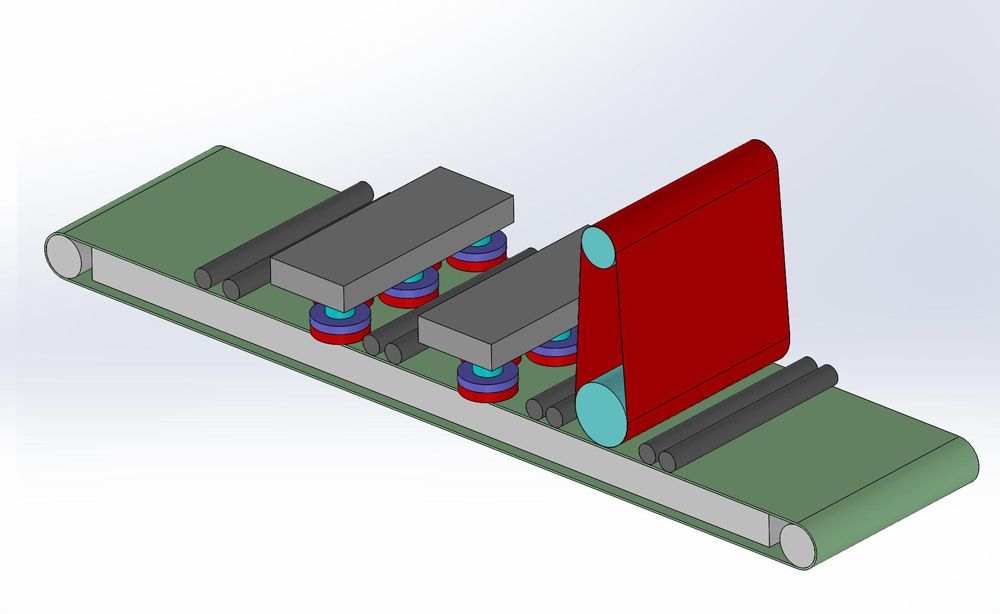

Brush plate deburring machine metal plate hollow deburring, chamfering treatment |

Brush plate deburring machine metal plate hollow deburring, chamfering treatment

Basic parameter of equipment:

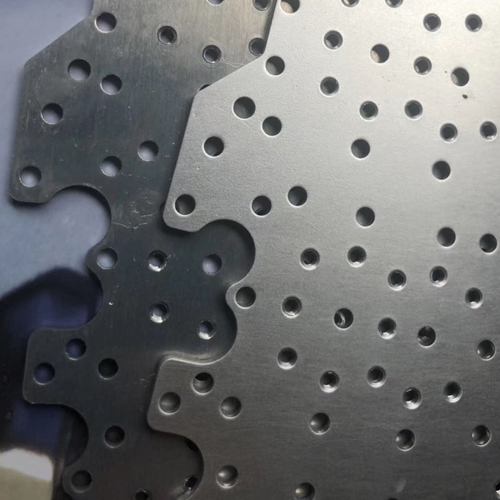

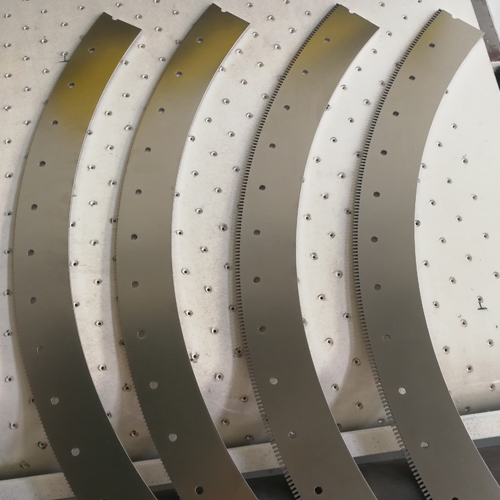

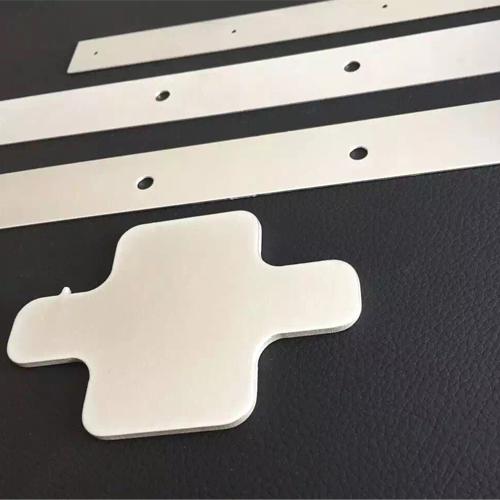

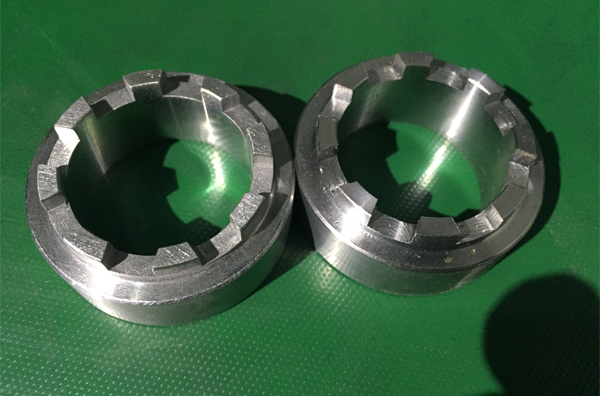

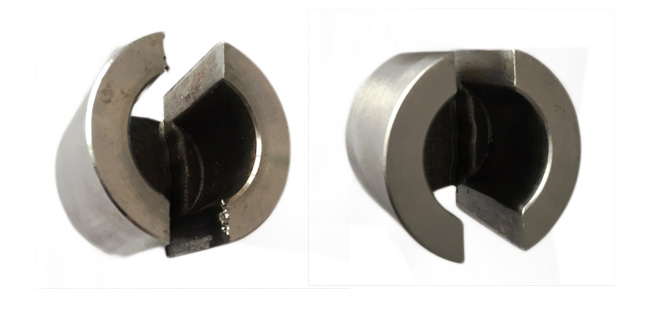

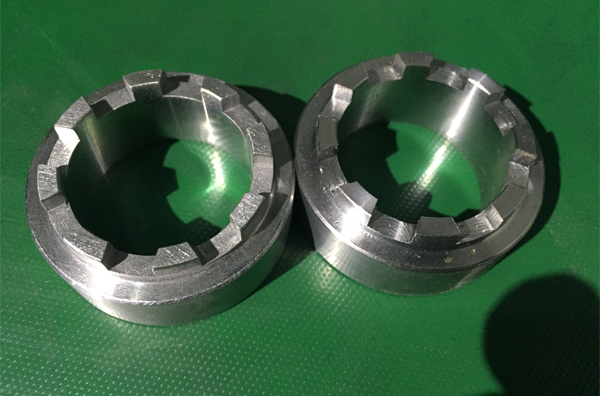

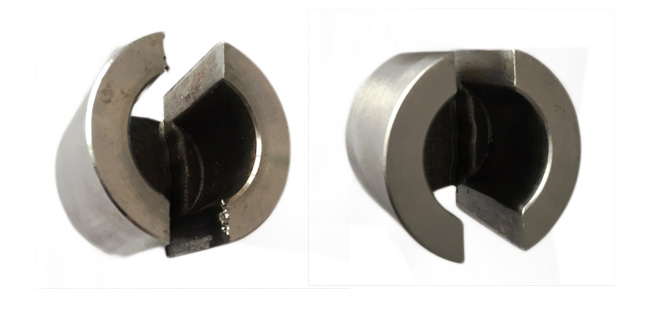

1. Scope of application: suitable for precision stamping parts, gear parts, auto parts, powder metallurgy parts, machining parts, etc.

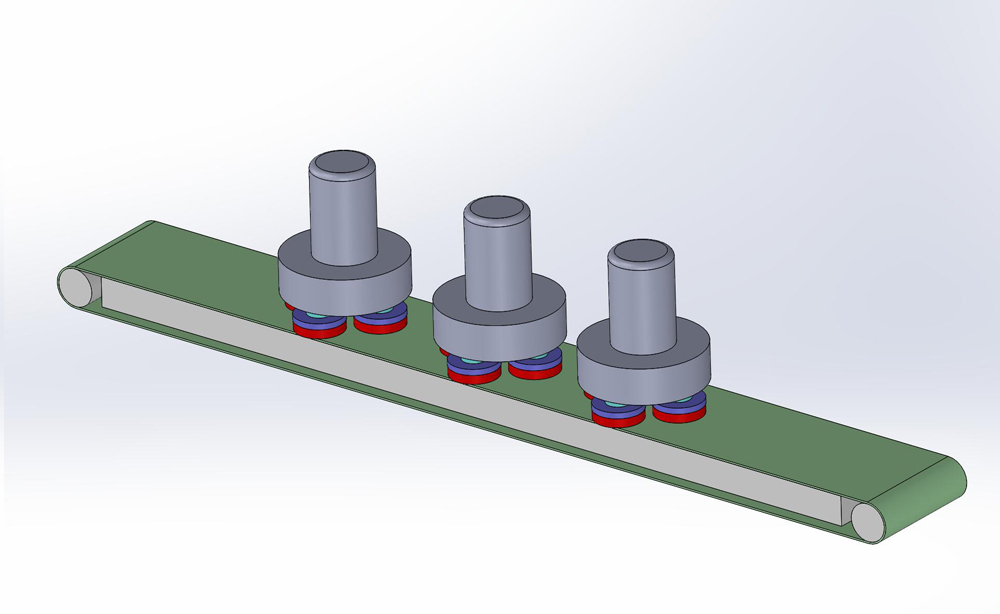

2. Equipment function: deburring the edges and holes of the workpiece, so that the surface of the workpiece is consistent, and all the edges and holes reach a uniform R arc.

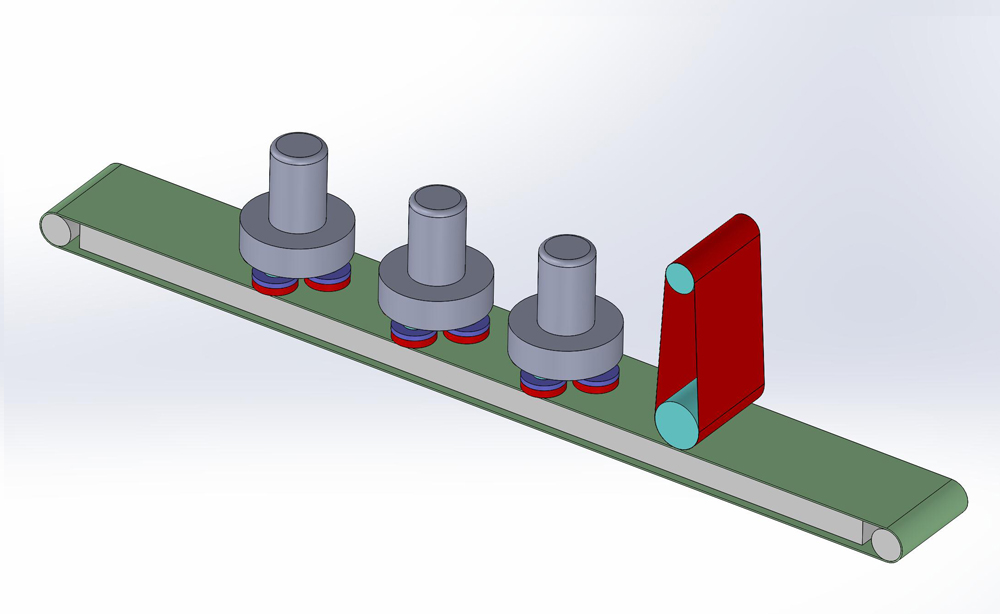

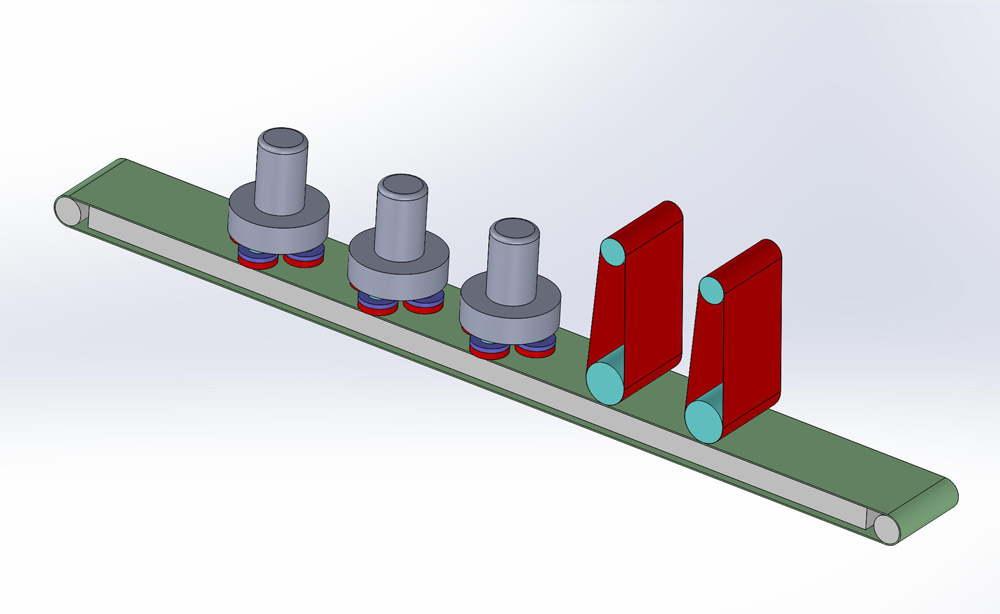

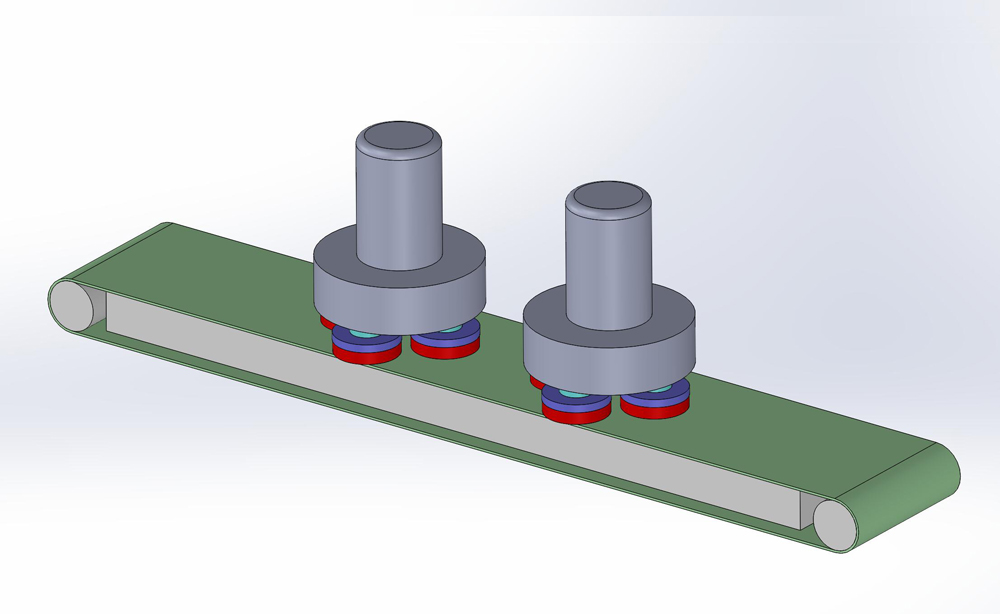

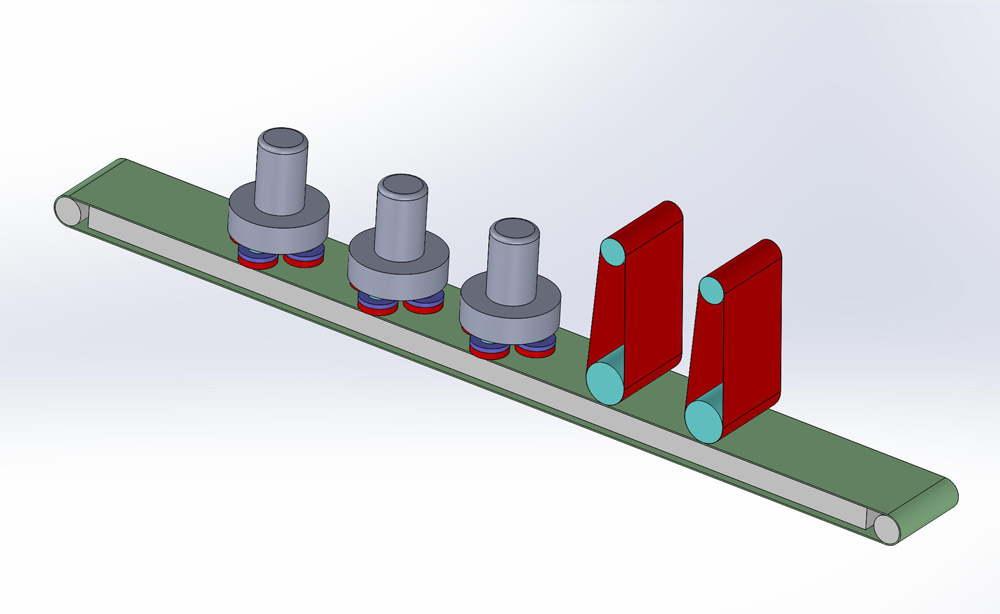

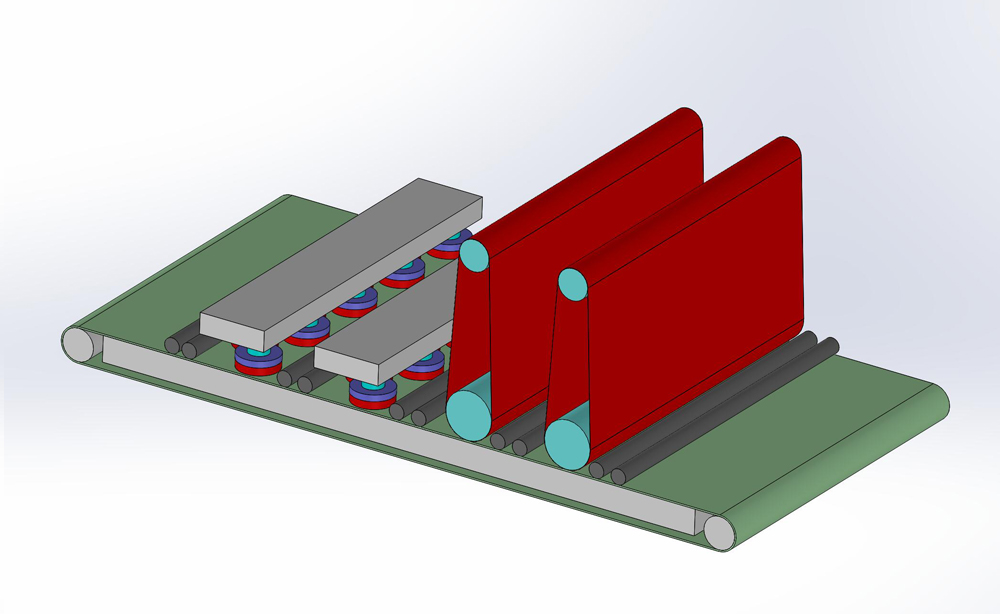

3. Equipment combination: Single or multiple combination structure of abrasive belt grinding station + disk brush grinding station

4. Equipment processing width:

300mm, 400mm, 650mm, 1050mm, 1350mm

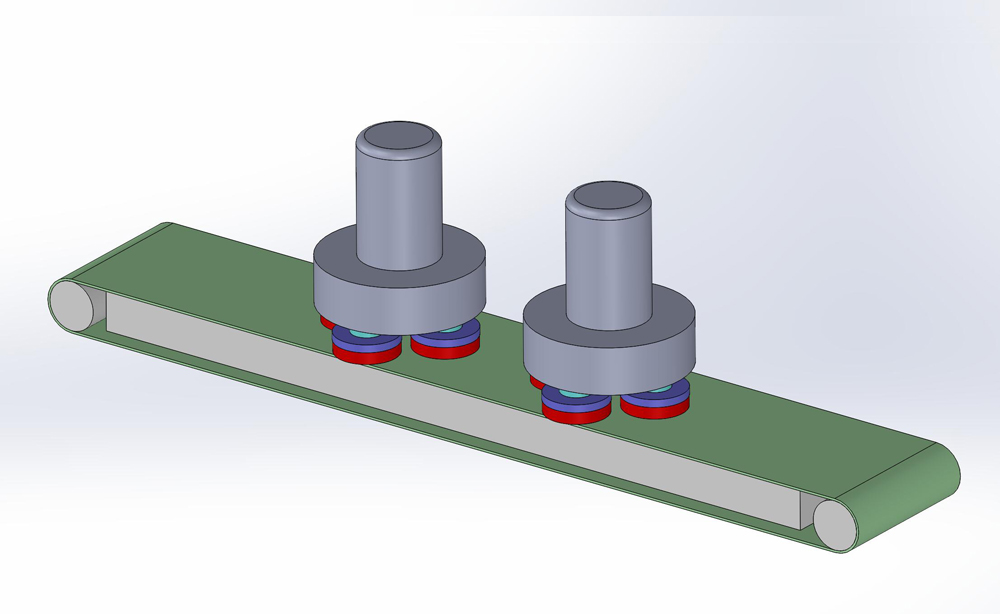

(1) The 300mm width is composed of three planetary arrangement disk brushes, a single disk brush rotation, the whole disk brush combination rotation

(2) The 400mm width is composed of four planetary arrangement disk brushes, a single disk brush rotation, the whole disk brush combination rotation

(3) The 650mm width is composed of 5 staggered disk brushes, two adjacent disk brushes rotate positively and negatively, and the entire disk brush combination swings horizontally in the vertical direction of the feed

(4) The width of 1050mm is composed of 7 staggered disk brushes, two adjacent disk brushes rotate positively and negatively, and the entire disk brush combination swings horizontally in the vertical direction of the feed

(5) The 1350mm width is composed of 9 staggered disk brushes, two adjacent disk brushes rotate positively and negatively, and the entire disk brush combination swings horizontally in the vertical direction of the feed

5. Equipment processing thickness:

1-100mm

6. Belt line speed: 18m/s (optional frequency control)

7. Disk brush rotation speed: 3000r/min (optional frequency control)

8. Disk brush revolution speed: 150r/min (optional frequency control)

9. Disc brush combination swing frequency: 120-280 times /min (optional frequency conversion adjustable)

10. Feeding speed: 0.5-6m/min (variable frequency adjustable)

11. Optional feeding method:

(1) Conveyor belt + rubber press roller clip feed (suitable for ordinary workpieces. Workpiece length ≥480mm)

(2) Strong permanent magnet adsorption feeding (suitable for carbon steel workpieces. Workpiece size ≥10mm×10mm)

(3) vacuum negative pressure adsorption feeding (suitable for stainless steel plate, copper plate, aluminum plate, etc., is not magnetically adsorbed. Workpiece size ≥50mm×50mm)

12. Four-column synchronous lifting, lifting height digital setting and reading, unit mm

11. The equipment is equipped with spray pipes before and after each station to provide grinding fluid. Magnetic adsorption outlet is selected to demagnetize the workpiece.

12. Equipped with automatic paper belt filter to filter grinding dust and provide grinding circulation grinding fluid to achieve environmentally friendly production.

13. Advantages of wet processing:

(1) wet machining workpiece cold processing is not easy to heat deformation;

(2) wet machining workpiece surface roughness is better;

(3) All the grinding dust is absorbed by wet processing, and the working environment is better;

(4) Wet processing consumables have a longer service life.

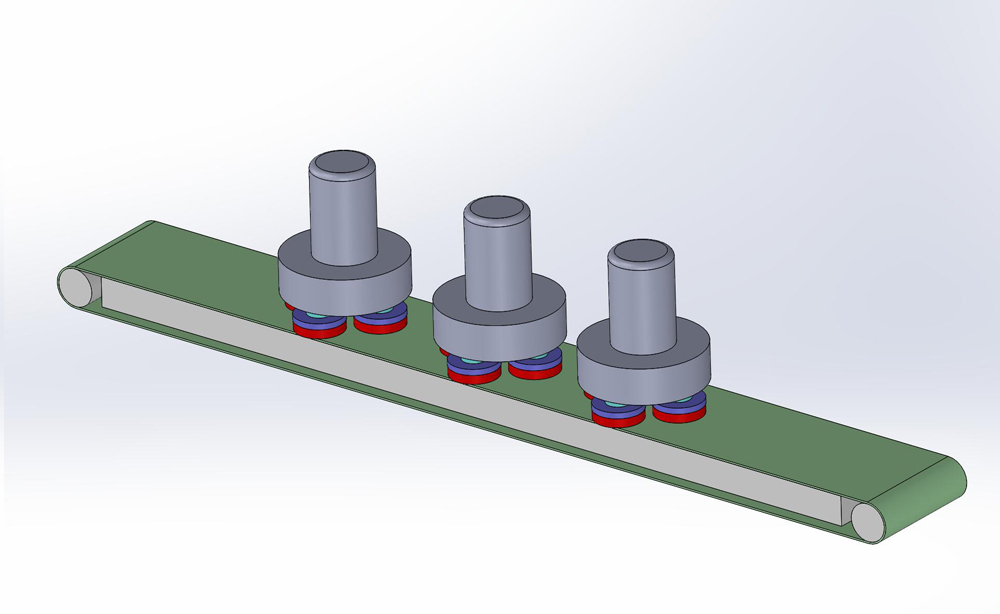

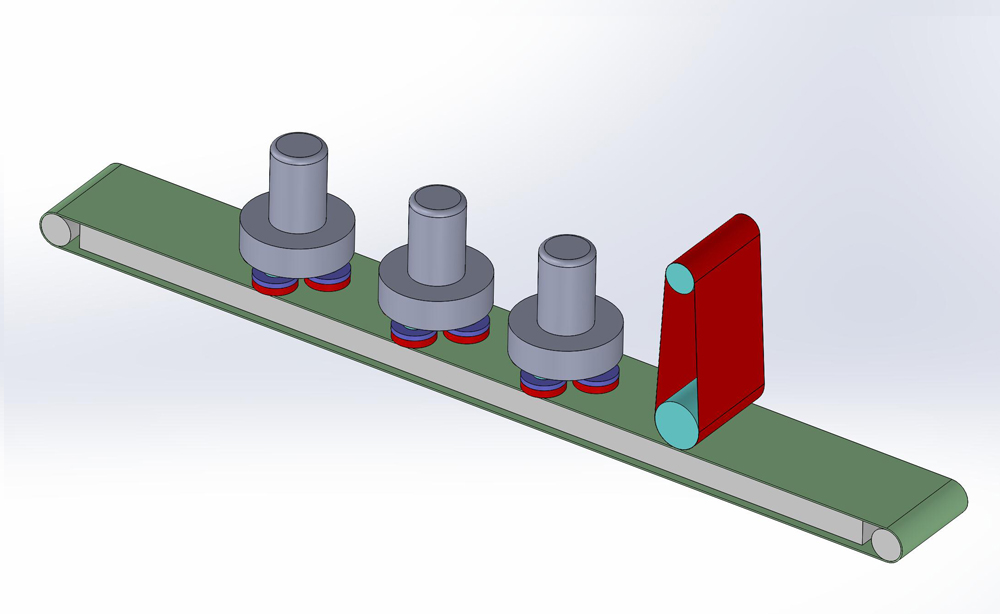

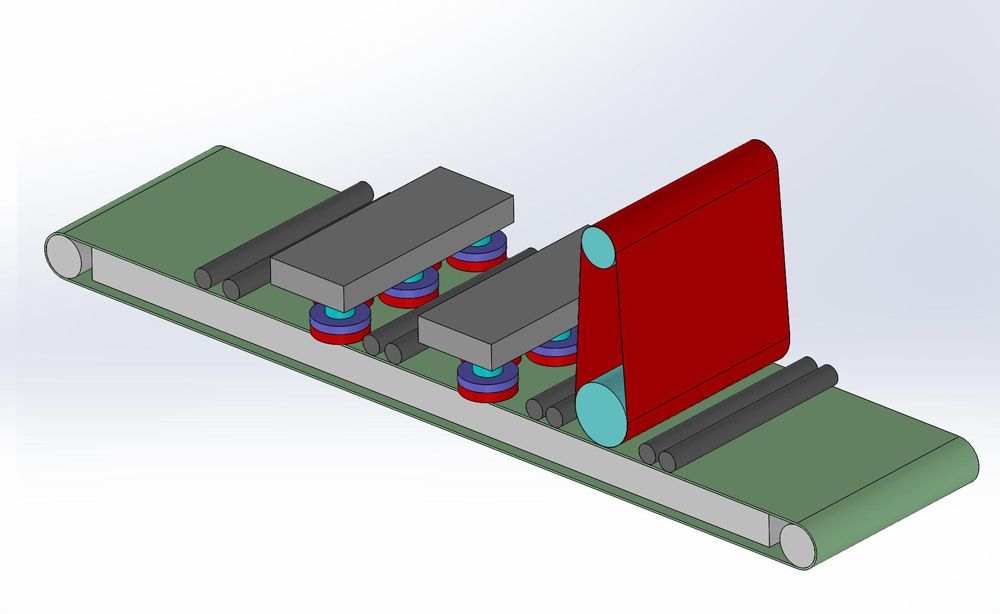

Equipment structure drawing:

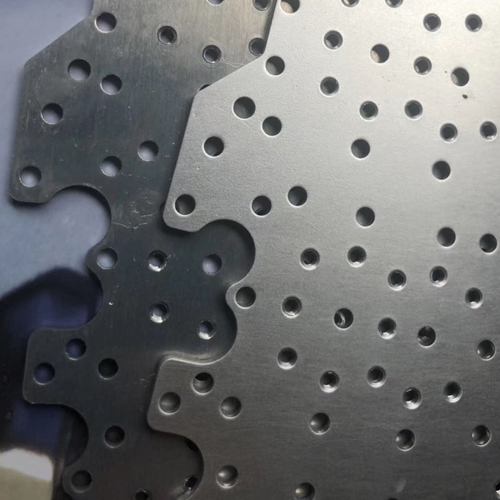

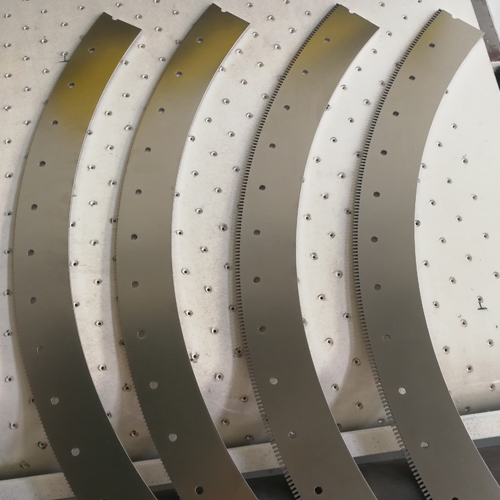

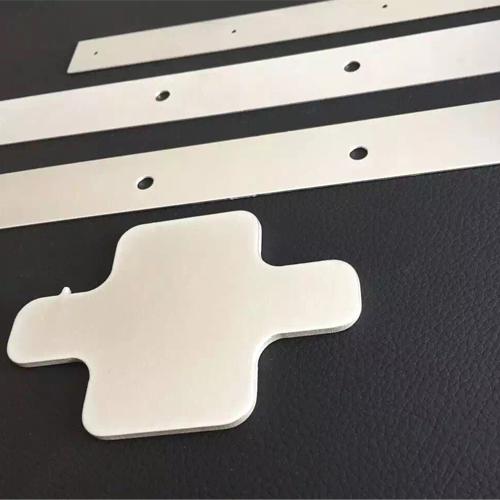

设备加工产品图: