position:Home > Products > Magnetic grinding/polishing machine

|

Magnetic polishing machine R-G110 |

| | Equipment type | R-G110 | |

| | Power source | 380V | |

| | Motor power | 4.0KW(Optional) | |

| | Equipment size | 1200*620*1100mm | |

| | Groove size | 1000*520mm | |

| | Reference quantity large processing quantity | 25-30kg | |

| | Processing speed | 0-60HZ | |

| | Mode of operation | Forward and reverse rotation and translation | |

| | Machine weight | 350KG | |

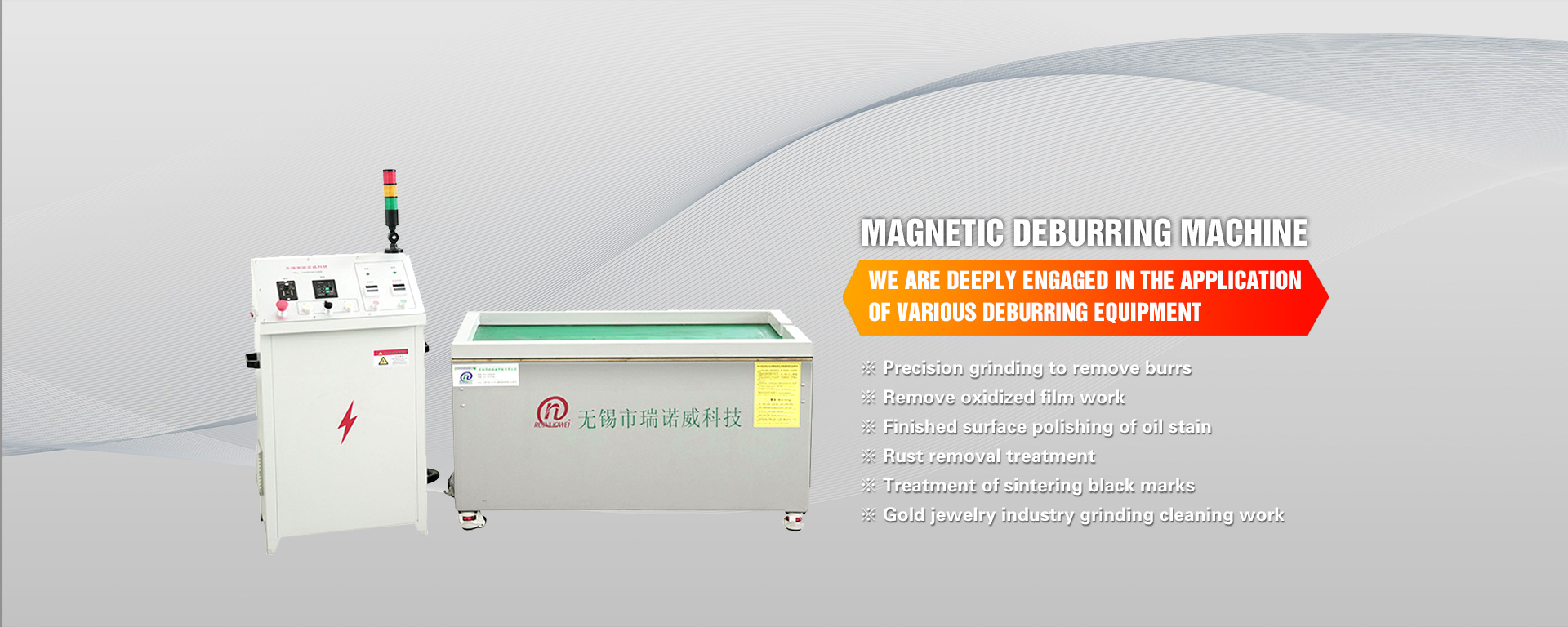

Working principle

Magnetic polishing/grinding/deburring machine is the use of high-strength magnetic field force, guide the stainless steel magnetic needle to produce rapid rotating motion to grind the workpiece, so as to efficiently remove the surface of the product burr, tip, polishing, polishing, peeling, welding spots and other grinding effects.

Equipment advantage

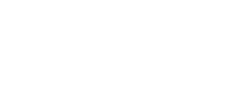

· Magnetic polishing/grinding machine can be used for all-directional non-dead Angle grinding of metal workpiece, including precision grinding of irregular parts such as internal holes, cracks, right angles and threads. The equipment performance is stable, efficient and fast, and the average grinding time is about 3-20 minutes.

· For irregularly shaped parts, removal of raw edges, polishing, cleaning and grinding are completed at the same time.

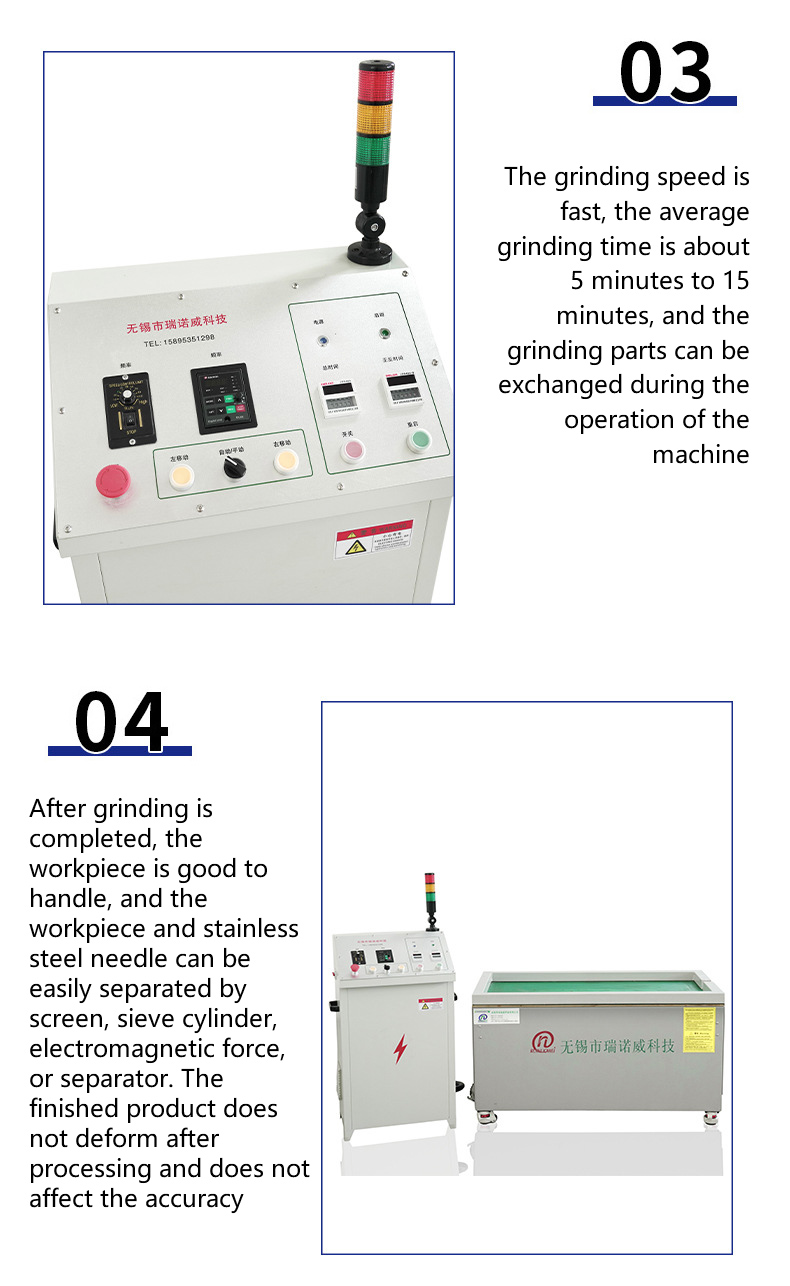

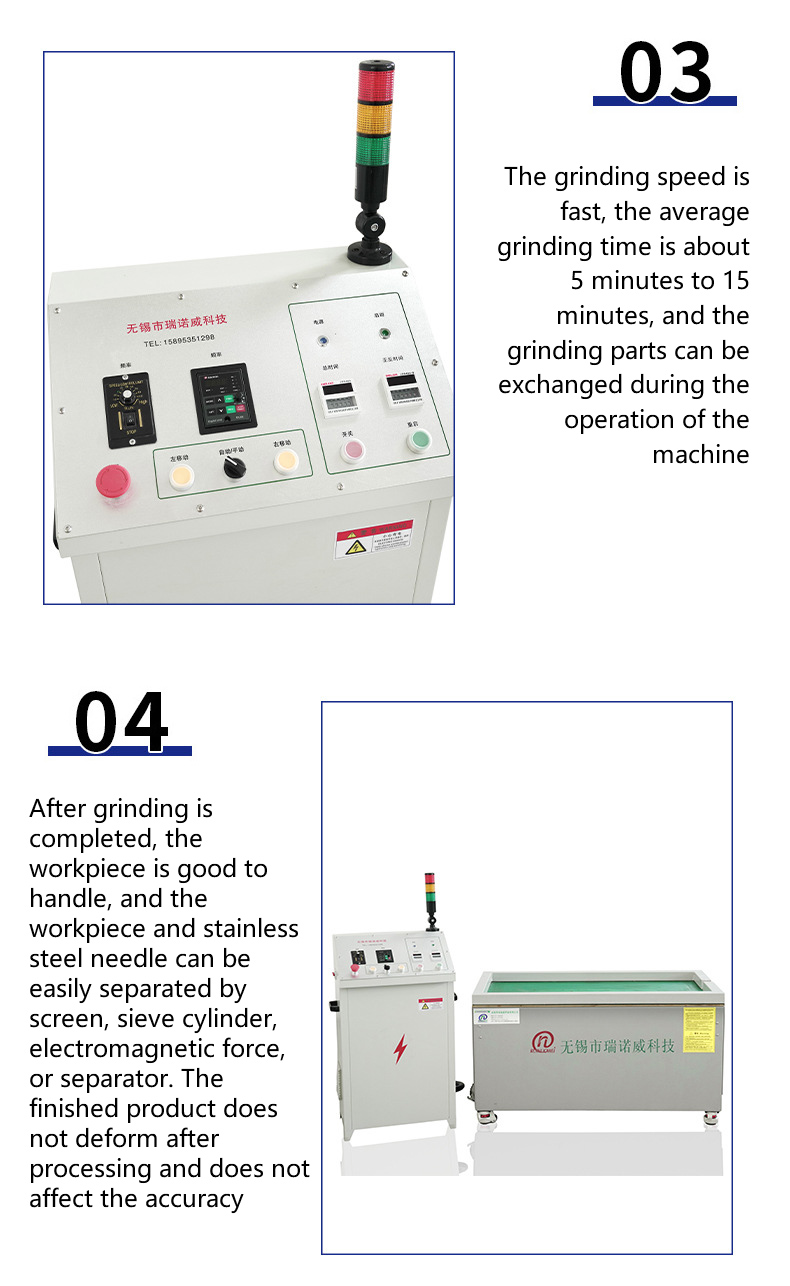

· Fast grinding speed, one-click operation, simple and safe, one person can operate multiple machines, low cost of consumables, high efficiency of grinding products.

· After grinding, the product will never deform, never damage the surface, and never affect the accuracy.

Scope of application

· Cooling accessories copper, aluminum, stainless steel, etc. (can replace pickling, electrolysis)

· Stainless steel, copper, iron spot removal

· Precision stamping parts, small hardware parts

· Precision spring, shrapnel and other parts

· Machine walking, CNC automatic lathe and other parts

· Zinc alloy, aluminum radiator, aluminum alloy die-casting parts

· Aviation accessories, medical equipment, surgical instruments and other parts

· Electronic, computer, communication and other parts

· Rail transit, sheet metal industry, high-end kitchen appliances and other parts